Customers today demand higher quality and durability from the products they buy. Not only do they expect these products to perform well; they also want finishes to look good and last longer.

As a "custom coater," PPG Coatings Services continually helps customers meet both challenges by offering a full array of finishing processes incorporating three primary coating technologies – powder coating, electrocoating (e-coat) and liquid painting. By offering access to this full scope of technologies, PPG Coatings Services offers the unparalleled ability to combine different coating materials and technologies in innovative ways.

The three technologies available from PPG Coatings Service complement each other to satisfy varying OEM requirements. Powder coat and e-coat deliver excellent performance and durability; yet there are applications where liquid paint materials finish attributes that cannot be achieved with powder or e-coat.

Liquid Paint Applications

Recent advancements in liquid paint technology have resulted in many unique formulations for niche businesses and applications. For example, a new liquid paint used on automotive exhaust system components is engineered to withstand very high operating temperatures, while a different product has been developed to give writing-pen barrels a “grippier, soft-feel” texture after curing. No matter how specialized the application, PPG Coatings Services has the experience and expertise to design and build an in-house coating system specifically for that use.

PPG Coatings Services also recommends liquid paint for certain applications to take advantage of the following characteristics unique to the technology:

- Liquid paints offer cure temperature versatility. Some formulas can be cured at room temperature while other can be cured more rapidly in a bake oven.

- Unlike e-coat or powder coat, liquid paint can be applied to completely assembled equipment such as large construction or material handling products.

- Masking is more feasible than with most other coating technologies.

Why Outsource?

A liquid coating system with the appropriate supporting equipment, such as the treatment system for process chemicals, represents a significant capital and staffing investment. For low-to-moderate production volumes, outsourcing can be a cost-effective way to obtain the advantages of professional liquid paint application without the added cost of running an in-house coating line.

When production volumes reach the levels that could justify an in-house system, the decision to outsource liquid paint becomes more complex than a "make or buy" evaluation. At that point, it also becomes a “strategic” decision that requires answers to two fundamental questions: “What is our business?” and “Do we want to run a coatings operation?”

Here are a few of the advantages of outsourcing with PPG Coatings Services:

- Project Analysis: PPG Coatings Services assists with development; then implements and supports the most effective processes to meet and exceed customer goals.

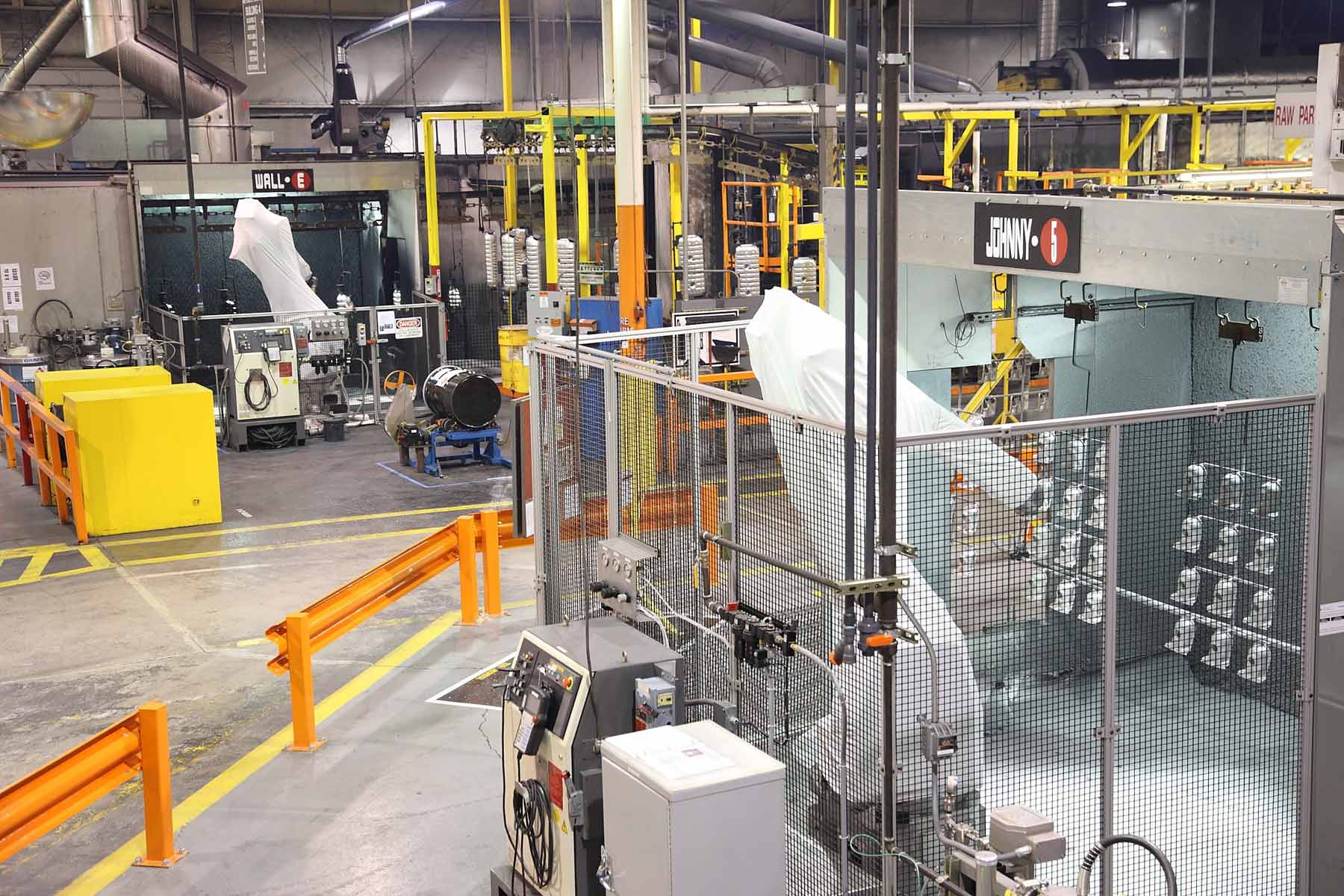

- Building and Equipment: PPG Coatings Services designs, builds and manages coatings operations for maximum efficiency specific to the customer’s product.

- Coating Application: PPG Coatings Services provides highly trained personnel for total custom coating system management.

- Parts Handling: The customer takes full advantage of PPG Coatings Services’ experience in packaging, logistics, assembly, inventory control, masking and specialized fixturing.

- Long-term Management: PPG Coatings Services’ unique “bundle” of skills and technical expertise allows customers to focus on their core businesses without the worries of operating a coating facility.

The process and techniques used in the application of liquid paint are often considered an art form. Guided by our team of professionals, PPG Coatings Services uses the latest coatings application equipment to:

- Control the coatings process for finish consistency

- Gain optimal results in liquid paint quality

- Closely controlling material utilization

- Conform to all environmental considerations mandated for liquid paint

Here are a few of the advantages of outsourcing with PPG Coatings Services:

- Project Analysis: PPG Coatings Services assists with development; then implements and supports the most effective processes to meet and exceed customer goals.

- Building and Equipment: PPG Coatings Services designs, builds and manages coatings operations for maximum efficiency specific to the customer’s product.

- Coating Application: PPG Coatings Services provides highly trained personnel for total custom coating system management.

- Parts Handling: The customer takes full advantage of PPG Coatings Services’ experience in packaging, logistics, assembly, inventory control, masking and specialized fixturing.

- Long-term Management: PPG Coatings Services’ unique “bundle” of skills and technical expertise allows customers to focus on their core businesses without the worries of operating a coating facility.

Learn More

PPG Coatings Services offers liquid coating services in multiple U.S. states and in other countries. Complementary technologies, such as electrocoating and powder coating, are available at certain locations as additional coating service options.

Well-known for the capabilities in its internal Technology Group, Equipment Division and experienced operating teams, PPG Coatings Services has earned a reputation for providing a total, integrated, cost-effective coating solution. Contact us today for more information!