Powder coating was the initial technology that set PPG Coatings Services (formerly MetoKote Corporation and The Crown Group) on the road to growth. Today, electrocoating represents the primary coatings application technology at our facilities, but liquid coatings also remain an area of industry-leading knowledge and expertise.

What materials can be liquid painted?

While powder and electrocoating technologies provide excellent performance and durability qualities, liquid painting is still often the preferred choice for non-metallic substrates. That’s because, in many instances, powder coating and electrocoating require curing at temperatures that can damage or distort the substrate.

Liquid painting is also an excellent technology option for finishing assembled components and products where powder coating and electrocoating may not be suitable.

Benefits of Liquid Painting?

Liquid paint is formulated using many different chemistries and selecting the right one for a given application is a science unto itself.

One of the most significant advantages associated with liquid paint is its capacity for easy, on-site color changes. Color change is not practical with e-coat and, while less difficult to execute with powder coatings, that color change process can be cumbersome, as well. Liquid paint systems, on the other hand, are designed for quick, easy color changes in one booth. They also are more flexible, as colors may be mixed on-site to given specifications.

Liquid paints also can be formulated to serve as a primer with special corrosion-inhibiting additives. While some formulas are designed for use as an intermediate coat with special fillers to build thickness and provide a smooth surface in preparation for top-coating, others are engineered for application over the intermediate coating–typically as a base color coat with special pigments and metallic elements for special effects.

There are also hard, clear formulas made for final top-coating that provide a deep luxurious appearance, as on automobile bodies and exterior components.

Advantages of PPG

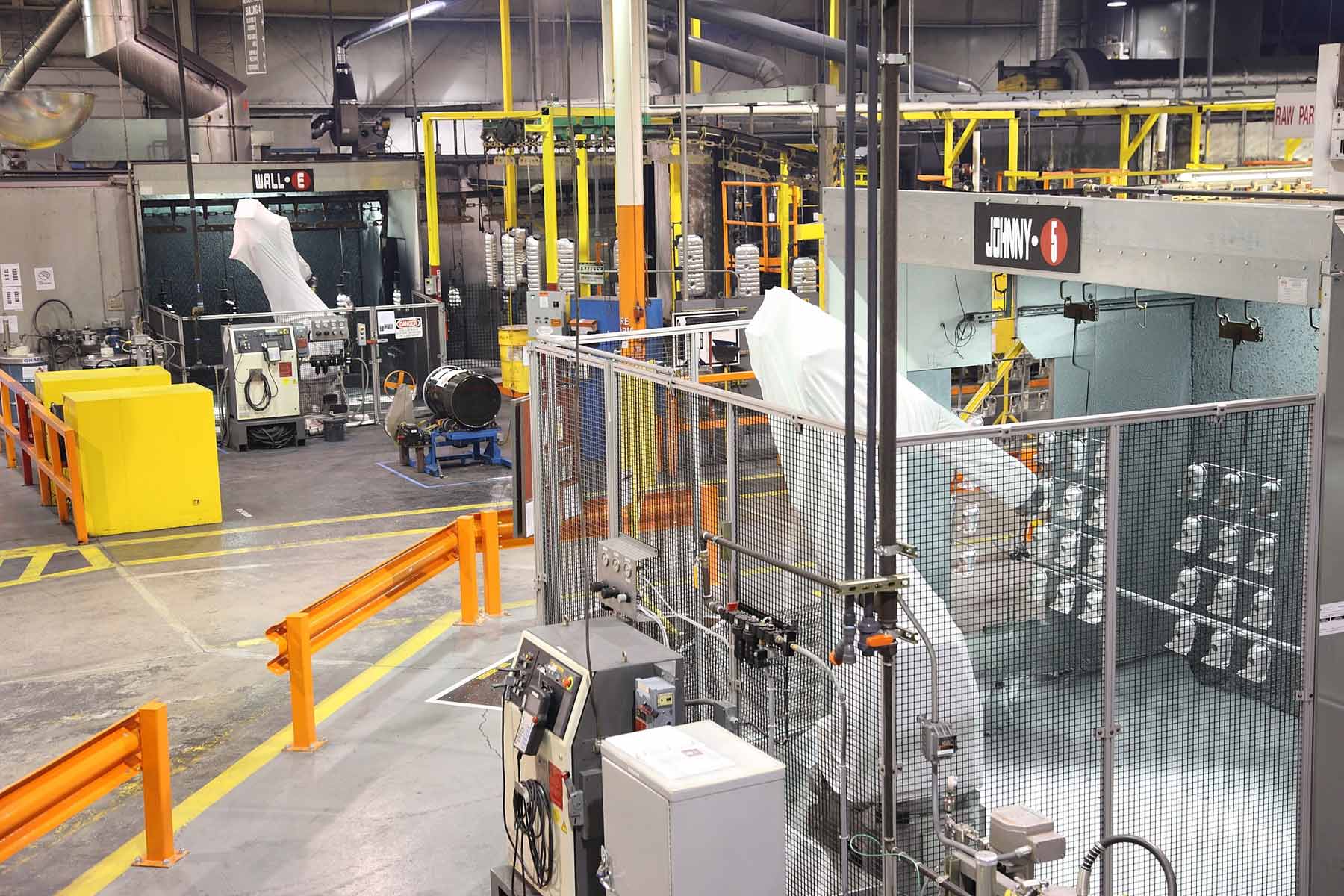

PPG Coatings Services applies liquid paint to a variety of products and substrates, including automotive steering gears, drive shafts, and hydraulic motors; truck wheels requiring special colors; tractor chassis assemblies and assembled machines. We also finish automotive exhaust system components with a special high temperature-resistant liquid paint.

Choose PPG

The various liquid paint applications available through PPG Coatings Services are supported by century of accumulated application and engineering capabilities. If your company has a production coating challenge that must be met – especially if the challenge requires unique application technology – count on PPG Coatings Services to get the job done.